Circular Economy: Minimization of Plastic Waste

- Economics Association Hyderabad Campus

- Mar 28, 2021

- 7 min read

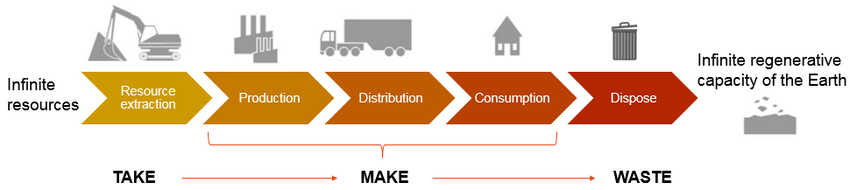

Plastics are versatile materials, but the way we use them (through a linear economy) is incredibly wasteful; 95% of material value is lost after one single-use. A linear economy generally follows the "take-make-waste" process, which means that the raw materials are collected and transformed into products used until they are finally discarded as waste (Fig-1).

Traditionally, it was thought that the Earth would automatically take care of any amount of waste because of its infinite regenerative capacity. However, we now know that the Earth does have an unlimited regenerative capacity.

The take-make-waste process we operate results in millions of tons of packaging ending up in landfills, incinerators, or worse, the environment. If we continue like this by 2050, the volume of plastic will have doubled. The flow of plastic into the ocean will have almost tripled, with ocean plastic stock quadrupling reaching over 600 million tons more clean-ups. The Earth may not be able to handle all this, even with the help of recycling. Therefore, this linear system is broken.

We must shift our focus to Innovation and business models that design a process to keep materials in use whilst working towards protecting and restoring our environment; we need a circular economy for plastic that never becomes waste or pollution. We need a structured approach to create a system that works in a manner without losing economic value and no plastic waste or pollution. The world needs to rethink how we make, use, and reuse plastics. Above all this, it is essential to redesign the system in which the material is used.

The Circular Economy

It is a systematic approach to economic development designed to benefit business, society, and the environment. Unlike the 'take-make-waste linear model, a circular economy is regenerative by design and aims to decouple growth from finite resources consumption gradually. The learning path redefines the economy and explores the circular economy's nuances, including the difference between biological and technical materials. These various opportunities exist to keep products in use. The circular economy's adoption is also seen as a route to improving the other aspects of society, for example, by generating a new labour force needed to reprocess (manufacture and repair) goods and materials that would increase in the circular economy model. In the long-run benefits of shifting from a linear to a circular economy are significant.

A Circular Economy for Plastic

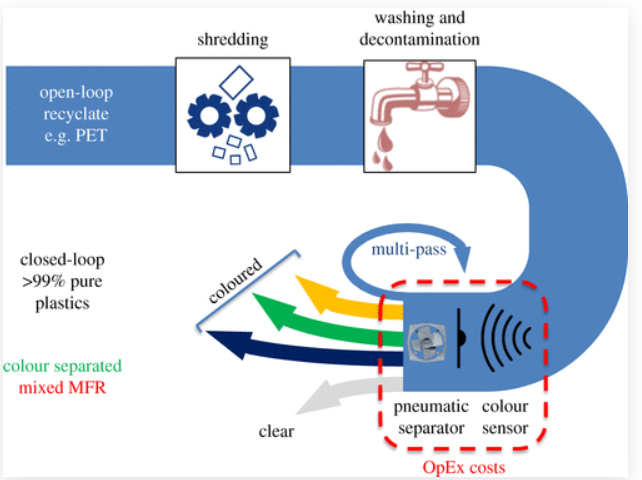

The circular economy in the plastics' context presents enormous challenges because of our current approach towards plastic usage and production (Fig-2). From the outset, the products should be designed to ensure no materials are lost, no toxins are released, and maximum use is achieved form every process, material and component.

Our relationship with plastics needs to get under scanning because the way we use them is not entirely environmentally sustainable. No-one wants to be in a position where we destroy ourselves. Is it possible to rethink how we use and design plastics to create a circular economy for plastic?

In the traditional linear plastic system, the many benefits of plastics are harnessed, but the negative consequences are ignored. Many documentaries, such as Blue Planet, showing the impact of plastic pollution on wildlife worldwide, have shocked and spurred a negative comment against the material.

So how can we delineate a circular economy by which the plastics minimally become waste or pollution?

Plastics Recycling

The circular economy concept's fundamental premise is to retain plastics within the utilization system for much longer. Recycling is an area gaining widespread attention at the global level in recent times. An increase in recycling offers potential for economic growth and reduced waste that could end up in the environment. Research by the British Plastics Federation has estimated that extending the recycling of plastics will create an additional 25000 jobs in the UK industry by 2030. It has been estimated that recycling offers profitable opportunities of a profit pool of about US$ 60 billion, 39% of which would derive from growth in mechanical recycling and the remaining 61% from developments in chemical recycling. At the same time, mechanical recycling is more profitable than chemical recycling.

Mechanical Recycling

In mechanical recycling, post-recycling plastics undergo various mechanical processes to recover to plastic polymers with minimal changes to the plastics' chemical and physical nature.

There are two types of categories open loop and closed loop:

Open-loop mechanical recycling, which is also referred to as cascade recycling, accounts for most recycling processes used worldwide (Fig-3). This type of process exploits mechanical methods, whereby the collected waste plastic is washed and shredded and mechanically sorted into plastic types in dedicated plastics reprocessing factory (PRF). Bulk commodities plastics such as low-density polyethylene (LDPE), high-density polyethylene (HDPE), polypropylene (PP), and polyether terephthalate (PET) are majorly recycled. Many physical processes are involved, such as flotation, melt filtration, electrostatic or magnetic separation. By far, the most common sorting process in PRFs used is manual and spectroscopic methods. The output from the mechanical recycling process are streams of plastics that are 94-98% pure. The recycling process would not meet food-grade standards and could not be used directly back in food packaging applications.

Consequently, it is a barrier to achieving closed-loop recycling in many packaging applications. The color separation remains an issue. However, the separation of colored recycled plastics from clear plastics is easy. Pigmented plastics are spectroscopically easily identified compared to clear, unpigmented recycling plastic. The clear plastic recycling output from these processes can be used when mixed with virgin feedstock for closed-loop recycling.

In closed-loop systems, the percentage inclusion of recycled plastics is relatively low. More than 99% is the virgin material content. For single plastic, depending on its intended end-use, it may have different types of additives such as stabilizers, pigments, plasticizers, and mould release agents. The additives are used to achieve desired chemical and physical properties in the mixed recycling input streams. The separated pure recycled plastics may have variations in additives, making the closed-loop recycling extremely difficult, given the need for returning particular material compositions to the processors for remaking the desired products. This explains why open-loop recycling is by far the most common outcome from mechanical recycling.

Chemical Recycling

Chemical recycling is the process in which polymers are broken down into either their constituent monomers or other small organic compounds that can be used as chemical feedstocks for polymerization to new polymers or exploited in other chemical processes. It offers opportunities for exploiting waste to generate value-added products for subsequent industrial applications and commercial products. The economic predictions indicate that potentially vast profits of US$37 billion are annually made from chemically recycled plastics. Petrochemical and plastics companies, which build and operate large-scale chemical plants, are seen as the place to invest.

There are two processes involved in chemical recycling:

Chemolysis is a generic term for a range of depolymerization reactions, including methanolysis and glycolysis, to form the constituents' monomers. It cannot be used for all polymers and is restricted to polymers such as PET, PA6.

Pyrolysis is the process of high-temperature annealing in the absence of oxygen, causing the polymer to decompose into small fragments or depolymerize. It is a method for plastics that do not easily depolymerize via mechanical recycling.

So how does chemical recycling compare to mechanical recycling? Despite significant development, all of the leading chemical recycling methods remain as pilot-scale operations. One of the considerable benefits of chemical recycling is the prospect of removing contaminants, pollutants, and toxin compounds from the plastic and preventing them from being sent for incineration.

What could be the vision for a circular economy for Plastics?

Following are some of the sustainable aspects forming the vision for implementing the circular economy for plastics.

Elimination of unnecessary plastic packaging through redesigning or innovation in the way we use them. Plastic brings many benefits, but certain non-sustainable aspects need to be eliminated to achieve a circular economy.

Reuse the products wherever possible, reducing the need for single-use packaging. Wherever relevant, reuse methods should be explored as an inner loop, reducing single-use plastics.

All plastics must be reusable, recyclable, or compostable. It requires a combination of redesigning and innovation in business models, materials, and reprocessing technologies.

All plastics must be free of hazardous chemicals, and the health safety of all people involved will be respected. It is essential to respect the health, safety, and rights of the people involved in the plastics processing industry and improve the working conditions in the informal sectors.

The above vision should be targeted by all concerned in the plastics manufacturing industries as well as users. Realizing these visions will require significant effort and investment. The importance of the life cycle perspective involved in it must be understood. All the stakeholders must aim for better economic and environmental outcomes recognizing that the time to act is now.

Is a circular economy achievable?

Despite many advantages vested in circular economy, most organizations globally still use the ineffective principle of linear economy. If circular economy is widely implemented, it would enable plastics for a vast range of applications and, at the same time, reduce environmental pollution.

Governments such as the European Commission have implemented policies promoting the circular economy, introducing an ambitious ‘circular economy action plan’ in 2015 to tackle pollution while also boosting economic growth, job creation, investment, and social fairness.

Conclusion

The future of the sustainable use of plastics lies in the widespread adoption of the circular economy. The vision for a circular economy for plastics is being implemented on the ground by a network of national initiatives by many countries, such as Plastics Pact, which is a globally aligned response to plastic waste and pollution.

If we want to free our Earth from extensive plastic wastage, we have to do more than just cleaning up. We have to rethink the way we make and use plastics. To do this, we need better materials and cleverer product design, and a new circular business model. A new way of thinking is critical to enable businesses and governments to achieve the targets; with a straightforward course of action and unprecedented global momentum, it is time to bolster innovation efforts to systemic change.

Comments